New timing belt backings: Greater variety of adjustment options

New timing belt backings: Greater variety of adjustment options

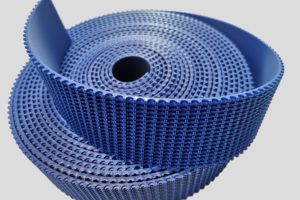

Sponge rubber is an extremely soft, elastic backing material with an open pore structure. Photo: BRECO

BRECO Antriebstechnik now offers three new backings for PU conveyor timing belts: sponge rubber, foam rubber and Supergrip FDA blue. This represents yet another expansion of the already broad field of possible applications for the popular BRECO® timing belts. They are available Europe-wide through the partner network of Mulco-Europe EWIV. Application expertise and technical consultation is included.

Sponge rubber

The advantages of sponge rubber are first and foremost that it is an extremely soft, elastic backing material with an open pore structure. It is highly absorbent and provides excellent friction characteristics. BRECO® timing belts with a sponge rubber backing are particularly suited for the transport of fragile goods such as china, glasses or bottles, for packaging and labelling machines and for wet and dirty areas. In the standard format, the sponge rubber applied to the BRECO® PU timing belt is orange and has a thickness of 20 mm. Additional thicknesses for application-specific adaptation are available on request.

BRECO® conveyor timing belt with foam rubber backing. Photo: BRECO

Foam rubber

The newly available foam rubber backing with approx. 20 Shore A is also extremely soft and elastic. Its pore structure and outer layer are closed, creating a smooth surface. Its friction characteristics are similar to those of Linatex, but foam rubber is slightly softer.

Foam rubber is made of the synthetic rubber material EPDM, which gives the material its resistance to ozone, weather and UV radiation. The closed-cell structure makes this backing material ideal for BRECO® conveyor timing belts used in wet areas.

Other uses include packaging and transport machines for cardboard boxes, paper, glass or other sensitive goods. By default, the material is offered in black and with a thickness of 10 mm. Other thicknesses are available on request.

Supergrip FDA blue for food processing machines. Photo: BRECO

Supergrip FDA blue

The new Supergrip backing in blue with FDA approval should interest anyone using coated timing belts in food processing machines and plants. Being TPU, the Supergrip Blue FDA material can be applied directly to the belt in an extrusion process. Likewise, adhesive application at a later point is possible. As Supergrip Blue FDA can be cut and welded, open-length products can be joined to form BRECO® V conveyor belts of any length. The blue timing belt back of the FDA variant has a hardness of 80 Shore A and a thickness of 4 mm. It is significantly more wear-resistant than PVC.

You’re interested in coated BRECO® timing belts? Our experienced application engineers will be glad to help you select the best PU timing belt for your current or planned transport drive.

Contact Mulco distribution partners now

Garbsen, 23.2.2022

Mulco-Europe EWIV