New timing belt backing for transporting hot products

New timing belt backing for transporting hot products

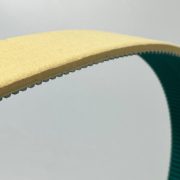

The joint of the timing belt with the 4 mm aramid felt backing must remain open. Photo: BRECO

A new backing material for extremely high contact temperatures is now available for transport drives using BRECO® timing belts. BRECO® timing belts with an aramid felt backing can withstand product temperatures of 250°C, for instance when products are leaving a furnace, without any problems.

Some timing belt applications e.g. in glass or aluminium processing, require extremely hot products to be transported briefly on the back of the belt. The new backing material “aramid felt 4 mm” is perfect for this application.

In-house experiments at BRECO have shown that contact temperatures of up to 250 °C are safe in moderate ambient temperatures of max. 80°C. For brief periods, the belt backing can even withstand temperatures of up to 500 °C. However, this should be an exception, as the exterior of the fibres will be damaged relatively quickly by such extreme temperatures.

The aramid felt combines well with the TPU of the BRECO® timing belt and can be fastened to this material without adhesive. Note that the belt joint on the back has to remain open, so there is a “butt joint” without bonding in the joint area.

The minimum pulley diameter for using an aramid felt backing on a BRECO® timing belt drive is 120 mm. Mechanical rework is not possible (for instance to reduce the thickness). The width tolerance is slightly larger (- 0.5 mm / + 1.0 mm).

You would like a timing belt application for transporting hot products or you are interested in coated BRECO® timing belts for other transport purposes? Our experienced application consultants will be glad to help you design your drive.

Garbsen, 14/06/2022

Mulco-Europe EWIV