Safely transport “overhead”

Safely transport “overhead”

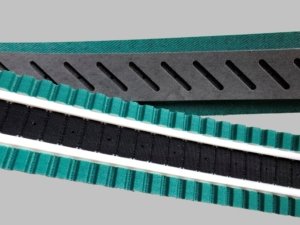

BRECOvacuum polyurethane timing belt. Photo: BRECO

With immediate effect, sales partners of Mulco Europe EWIV are offering a new timing belt-pulley system for all material handling systems: BRECOvacuum. This innovative vacuum system enables “overhead” transportation of films, papers, glass panes or thin metal sheets in a safer and more efficient manner than with conventional vacuum timing belts made of polyurethane.

The suction channel of the vacuum timing belt is provided with an extremely wear-resistant woven fabric during manufacture, and a specially designed zone that is free of tension members. Nylon coating on the back of the belt prevents undesired sagging and tilting of the timing belt as a result of the suction effect.

The sealing strips are formed into an integral component of the timing belt during the production process. Its cross section is an optimum combination of sealing efficiency and flexibility for pulley rotation.

The geometries of the synchronising pulleys and suction ledges - which are, as a rule, highly complex— are precisely tailored to the timing belts in the BRECOvacuum system. This reduces wear from faulty tolerance synchronisation between the elements, as well as increases the service life of the system. Synchronising the individual system components with one another helps minimise vacuum loss.

BRECOvacuum is available in the pitch AT10 with a belt width of 50 mm or 75 mm.

Garbsen, 12.07.2020

Mulco-Europe EWIV