It is the details that truly matter

It is the details that truly matter

What do coffee and PU timing belts have in common? Photo: Mulco

Coffee enthusiasts know that all too well: Coffee beans and water - just two ingredients, but the list of variables that might affect the result is practically infinite: the bean, the roast, the degree of grinding, the water pressure, the brewing temperature, etc. - every little detail matters. PU timing belts are just the same...

They also consist of “just” two components: The tension member and polyurethane. We would like to show you how BRECO responds to current trends in drive technology and automation by offering suitable solutions with exceptional “ingredients”.

Hygienic design is key for production lines in the food industry. Machine lines need to be smooth, with few grooves, undercuts and counterbores. That makes cleaning easier and prevents dirt from accumulating.

Stainless steel is often the material of choice to prevent pressure washers, water and chemicals from causing corrosion damage. But how compatible are timing belts with these ambient conditions?

Some modifications are required to make them suitable for the food industry.

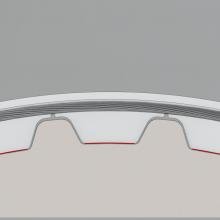

The narrow coiling nose of a conventional timing belt is visible at the tooth root surface. Graphic: BRECO

The timing belt for contact with food: BRECOprotect®

This is because timing belts have “coiling noses”. These are small notches at the tooth root surface where the tension member is uncovered. In this area there is a risk of the steel tension member corroding due to contact with cleaning agents and water.

A stainless steel tension member is an easy way to solve this problem, but is slightly more expensive. BRECO offers an interesting alternative: The Porta Westfalica based experts have modified their extrusion process for the “protect” timing belt so that the tension member at the tooth root surface is completely enclosed, eliminating the coiling nose.

These belts are no different from other BRECO timing belts where exterior geometry or precision is concerned. The design of these timing belts without a coiling nose also prevents the build-up of concealed and difficult-to-remove deposits and facilitates the cleaning process. Problem solved - but not entirely!

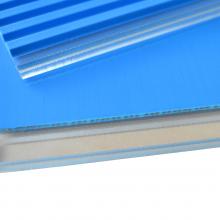

While the steel tension members of endless joined BRECOprotect timing belts are completely enclosed, the ends of the open length version are not covered. But BRECO developers have found a solution for this problem, too: End seals made of transparent polyurethane cover the belt ends. The steel tension member is now completely enclosed in PU. Problem solved!

Covered face side of a BRECOprotect® timing belt. Photo: BRECO

Polyurethane for the food and pharmaceutical industry

In the food industry, timing belts need to be particularly resistant to cleaning fluids and water. Water, often from heated pressure jet equipment, is used to rinse the belt after the actual cleaning process.

Many synthetic materials are “sensitive” to long-term exposure to warm and humid conditions. Conventional polyurethane timing belts often have a very limited service life under these conditions, particularly due to hydrolysis.

For the protect timing belts, BRECO uses the specially adapted polyurethane TPUAU1. As an option, it is also available in different degrees of hardness (TPUAU2 and TPUAU3). All of these materials are characterised by excellent resistance to cleaning fluids and water.

Legal requirements are the final hurdle for using timing belts in the food industry. In Europe, these are the directives of the European Commission, for instance (EU) 1935/2004, (EU) 2024/2006 and (EU) 10/2011. These directives govern the declaration of products along the entire production and delivery chain including traceability, ensuring “good manufacturing practices” and the banning or permissible limits of specific substances. A declaration of conformity of this type is available for all BRECOprotect® timing belts.

For export of machines and machine lines to the American market, the polyurethane materials TPUAU1-3 meet the requirements of FDA CFR § 177.1680 issued by the FDA (Food and Drug Administration) for contact of timing belts with dry foodstuffs. The corresponding material data sheet confirms conformity with FDA regulations.

A declaration of conformity for products coming into direct contact with food is also required more and more frequently. That means it is no longer sufficient to declare the compliance of the materials in use with the above directives. It is now necessary to test the overall material compound of the product for suitability for direct contact with food. These “migration tests” were successfully completed for the BRECOprotect® product range and the results are confirmed by a certificate.

Compliance with the GMP Directive (EC) 2023/2006 (Good Manufacturing Practice) is also necessary to receive this certificate. Only this guarantees the cleanliness or purity of the product following the manufacturing process.

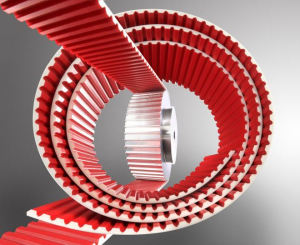

BRECOmove AT10 polyurethane timing belts. Photo: Mulco

The unyielding: BRECOFLEXmove and BRECOmove

BRECO has developed the timing belts of the “move” family especially for high-performance drives and linear drives with high positioning accuracy and strong dynamic characteristics. But how does a high-performance timing belt differ from a standard timing belt?

Initially you might assume that it’s the tensile strength or breaking strength. But far from it. A thought experiment will illustrate the situation: If the load on a timing belt increases, the permissible tensile elongation for a perfect tooth mesh with the belt pulley is reached before the permissible tensile force. For this reason, the crucial factor for the performance of a timing belt is its tensile stiffness.

BRECO engineers have therefore developed a new steel cord tension member whose belt stiffness is approximately 70% higher than that of its predecessor. This, in turn, permits greater tensile forces and a higher power density.

Due to the higher forces that BRECOmove and BRECOFLEXmove timing belts can transmit, the load on the tooth face and tooth root surface also increased. For this reason, the Finite Element Method (FEM) was used to optimise the surface pressure distribution on the tooth.

In addition, a friction-optimised laminate coating has been applied to the tooth side. Both measures reduce the peak loads and the work of friction between the timing belt and the belt pulley by as much as 25%. Despite the higher tensile stiffness, the new steel cord also offers greater flexibility, so that smaller minimum diameters with and without contraflexure are possible.

BRECOgreen polyurethane timing belts. Photo: BRECO

The eco-friendly: BRECOgreen and BRECOFLEXgreen

Climate and environment protection have become a matter of survival for humanity in the 21st century. But what can we do as a company? At BRECO we are dedicated to optimising our energy consumption, modernising our production facilities and using renewable resources. But don’t products made of renewable resources have functional disadvantages?

Dr. Jürgen Vollbarth, Head of Sales and Product Development at BRECO explains: “Our green product family proves that protecting the environment and performance do not have to be in opposition. The polyurethane we use for these timing belts is made of up to 37% renewable resources. These resources, incidentally, are not taken from the food chain. We make a point of that. The majority of them replaces the resource-critical mineral oil component.”

Even with this high renewable material content, the strength and resilience of the “green” material matches that of a comparable, mineral oil based thermoplastic polyurethane. BRECO’s “green” timing belts are perfect as an absolutely equivalent, eco-friendly product for all companies who have made sustainability part of their profile.

Garbsen, 28 February 2019